More than 60% of the electric motors operating in India are in the IE1 category. With the developments in efficiency standards from IE1 to IE4, it is worthwhile to look at the cost-benefit analysis of all the existing motors operating in the plant.

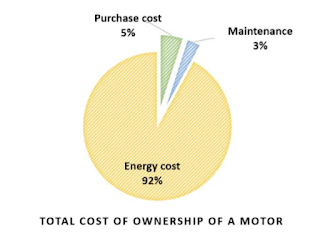

In Motors, we should consider the total lifetime cost rather than just the initial cost, As shown in the picture, the operating cost is several times higher than the purchase cost of the motor assuming an average life of 20 years under normal maintenance. This is similar to an air conditioner in the house, where the running cost is very high compared to the purchase cost.

Consider the following example of 15KW/20HP, 3-Phase, 415 V, Cage Motor at full load to understand the cost and efficiency effect.

For this example, let’s calculate the annual savings in replacing an IE1 motor operating 3 shifts a day at full load with an IE4 motor.

The above was assuming the replacement of a new IE1 motor with a new IE4 motor, resulting in an investment payback of 14 months. However in reality existing motors are generally old or rewound in these cases the payback period would be as low as 5 months.

1 Comment

[…] Savings: Incorporating VFDs can lead to energy savings ranging from 35% to 60% in commercial HVAC systems by fine-tuning motor speed for optimal […]

Comments are closed.