Over 40% of all electrical energy consumed in India is used by electric motors. Thus improving the efficiency of electric motors and the driven equipment can save energy, reduce operating costs and improve our nation’s productivity to be competitive in the world market.

WHEN SHOULD YOU CONSIDER BUYING AN ENERGY-EFFICIENT MOTOR

- Any new installation.

- Expansions/ Modifications to the existing setup.

- The purchase did as a combined system(e.g. along with Compressors, HVAC, Pumps, or any others.

- Replacing old continuous-operation motors which have undergone multiple rewinding.

- Replacing oversized and under-loaded motors.

- Replacing old slip-ring motors/DC motors with AC cage motors.

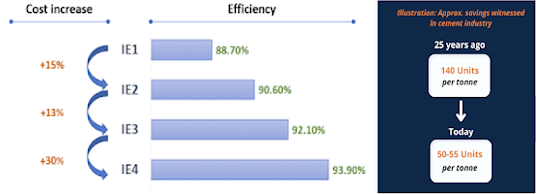

International Electro-technical Commission (IEC) standards of IE1, IE2, IE3 & IE4 came into existence in India a few years ago replacing the earlier adopted European Efficiency Classification standards of EFF1, EFF2 & EFF3. There are two key differences between the standards. On EFF the stray loss is assumed to be 0.5% of input power, whereas in IEC standards over EFF standards. Secondly, the order of efficiency is different between the standards.

Thanks to the increased adoption of IE3 motors in there has been a significant reduction in power consumption across various industries now.

In order to replace an existing motor with an energy cost, no. of hours of operation, loading on the motor, age and the current efficiency of the motor. As an example, for a 10-year-old, full-load motor under continuous operation, the payback period would be as low as 10 months.