- Unpack the Motors

- Motor to be installed securely using the appropriate Bolts & Nuts by applying the required torque.

- Over tightening of bolts may lead to damages to foot/flange of the motor

- Under tightening of bolts may lead to excessive vibrations of the motor

- Location of the motor to be such that Cool air has free access and can pass unobstructed over the motor

- For outdoor installation, Canopy (Motor Cover) is recommended to avoid water entry

- Before connecting the motor to electric supply, Check the following

- Free Rotation of the rotor

- All phase resistances to be equal (Use Multimeter)

- Check IR value, it should be > 1 MegaOhm (Use Multimeter or Meggar)

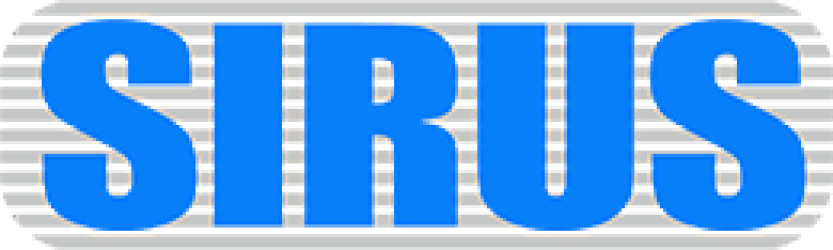

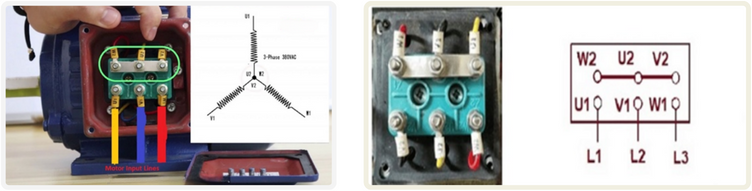

Once the above are checked, make the connections as shown below

Case 1: Star Connection (For Motors of 2 HP & Below)

Case 2: Delta Connection (For Motors of 3 HP & Above)

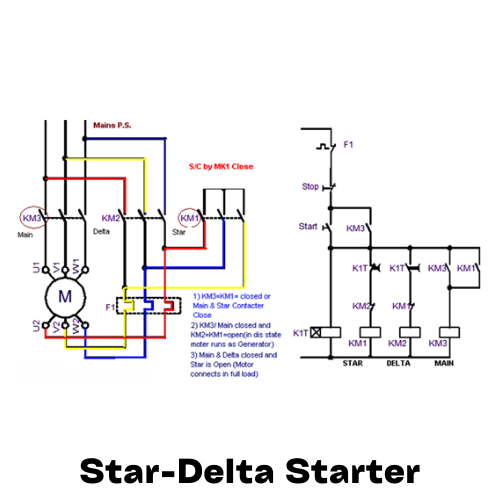

Case 3: Star Connection (For Motors of 10 HP & Above)

Remove all Shorting Links and connect Star-Delta Starter

Precautions to be taken:

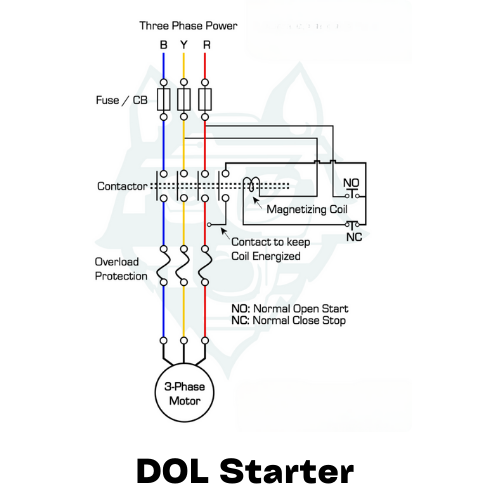

- Every motor needs a Starter with Switch, Over load protection and Short Circuit Protection. Single phase preventer is also suggested.

- Motors can have Switch fuse unit, MCB or MCCB or MPCB for Over load

- Protection Set FLC given on name plate for Over load Protection

- Fuse rating for Short Circuit Protection as per the motor rating

- There should not be any loose connections. All connections to be made secure.

- Voltage at motor terminals should be equal to ensure availability of all three phases

- For Belt-Pulley, Chain-Sprocket & Gear Coupling applications, Optimum belt tension & Alignment to be maintained to avoid excessive load on Shaft & Bearings

- The coupling parts to be fitted on the motor shaft are to be properly balanced.

- The bore and key way are to be machined accurately within tolerance for the bore diameter of H7

- The coupling parts or pulley must be carefully fitted by means of special tackle for which a tapped hole is provided at shaft end. Hammering must be avoided since it might damage bearings. The tackle can also be used for removal of coupling

- If the motor has been stored for longer than 18 months, drain out the grease and refill back

- Use appropriate size of cable for connecting the motor. While connecting the cables to motor terminals please ensure that the cable is properly secured and clamped and it does not exert any tension on terminal.

- For detailed instructions, please refer to Maintenance manual supplied along with the Motor

- For immediate reference, the diagrams of DOL Starter and Star-Delta Starter is given below

Important Note: Overload, failure due to wrong connections or wrong alignment, Breakages and Running on 2-Phase supply do not fall under manufacturing defects